Products

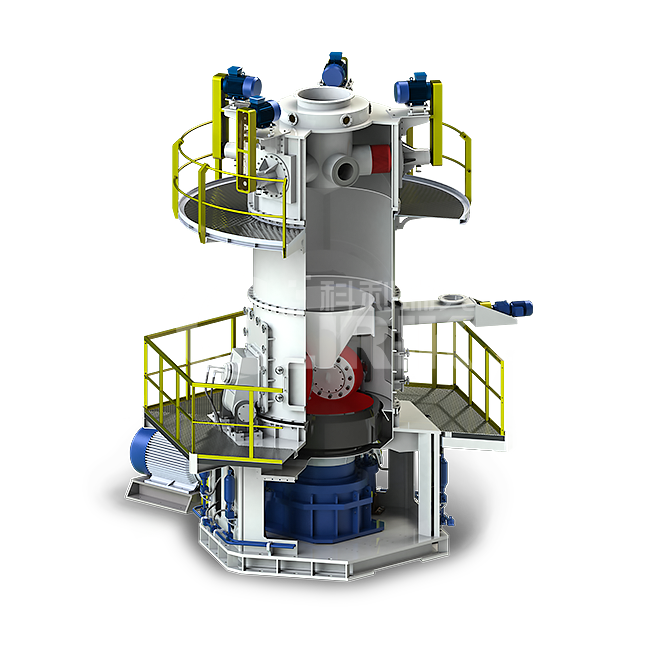

Ultra fine vertical roller mill

CLUM series ultrafine vertical roller mill was produced by Shanghai Clirik Machinery Co., Ltd. Relying on 12 years of experience in the production of ultrafine powder and based on German and Taiwan ultrafine vertical mill technologies. The top technical team members were joined this project. Besides, high-quality wear-resistant parts are used to develop milling equipment which in a real sense marks the first secondary classifying technology in mainland China, having product fineness of 400-6000 mesh.

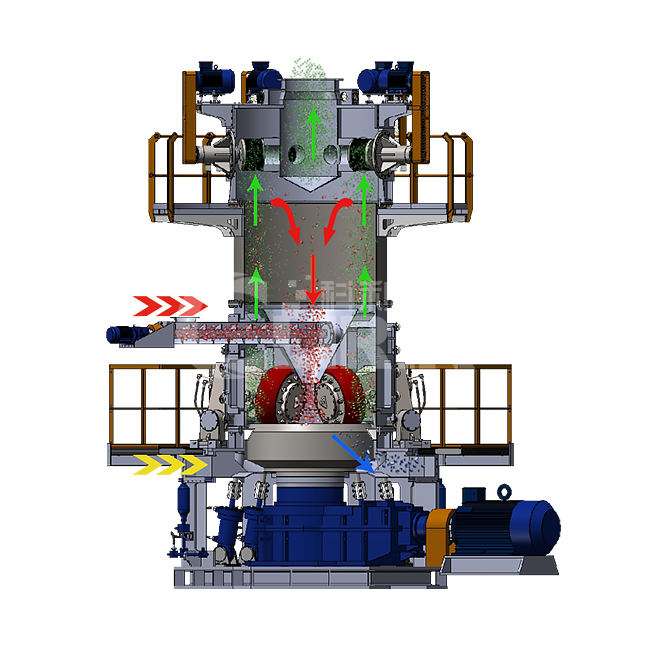

The grinding disc is driving by motor through reducer. The material falls to grinding disc from the feed opening. The materials are driven to the edge of disc by the centrifugal force and crushed into fine powders by rollers. Then, the hot air from the nozzle take the fine powder to high effiency classsifer.The qualified powder are taken by the air to the powder collector to be collected, while the unqualified powder are sent back for regrinding.

Working Principle of Vertical Roller Mill

l) High efficiency

Features of ultra fine vertical mill

Under the same finished final size and the same motor power, the capacity of stone micronizer is twice as much as jet mill, mixing grinder and ball mill.

2)Long lifecycle of spare parts

The ring and roller are forged by special material with high utilization. Under the same grinding material and finish special size, the lifecycle of spare parts is about one year, which is 2-3times longer than impact mill or turbo mill. Furthermore, the lifetime can reach 2-5 years for grinding calcite carbonate.

3)High safety and reliability

As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

4) High fineness and flexible adjustment

The final fineness of the grinding materials can be adjusted between 325 meshes and 3000 meshes, and the product fineness can reach D97≦5um.

5)Environment-friendly

The application of pulse deduster and muffler greatly alleviates dust pollution and noise.

Technical parameter of ultra fine vertical mill

| Measurement items | Name | Take an example inultrafine ground calcium carbonate | |||

| Output | t/h | 13-17 | 11-13 | 9-10 | 7-8 |

| Specific surface area | c㎡/g | 11000±500 | 13500±500 | 15000±500 | 17000±500 |

| 325 mesh remaining amount | % | 0.015 | 0.015 | 0.01 | 0 |

| Less than 2ìm powder | % | 34±2 | 40±2 | 45±2 | 50±2 |

| Median partical diameter D50 | ìm | 4.3 | 3.7 | 2.4 | 1.86 |

| Partical size distrihution D97 | ìm | 30 | 25 | 20 | 15 |

| Partical size cut point | ìm | 80 | 48 | 38 | 28 |

| Close apparent specific gravity | g/cm³ | 1.18 | 1.06 | 0.90 | 0.85 |

| Loose apparent specific gravity | g/cm³ | 0.45 | 0.40 | 0.34 | 0.32 |

| Moisture content | % | less than 0.3 | |||

| Sedimentation volume | 1 hour later | 24 | 27 | 33 | 43 |

| Energy consumption | kw/t | 38-40 | 40-50 | 47-53 |

50-53 |

Company strength

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a pioneer enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

So far, we have established a whole production chain, the products covermicro powder grinding mill, high pressure grinding mill, European version coarsegrinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on. They are widely used in the industry of mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering and so on. Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, and America, etc.

We still insist on the communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always is in the domestic front. Based on the principle of constant innovation and quality guarantee, customer foremost, we are able to provide our customers not only the highest quality products at the most favorable price but also the most reasonable solution, such as the selection of the equipment,optimized process configuration and a full range of technical support, therefore we always follow your steps, pursue your value and achieve your benefit.