Products

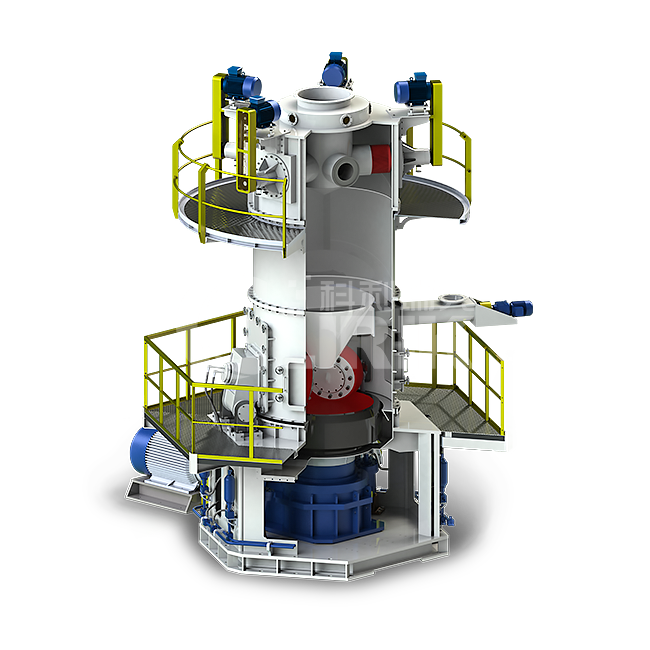

CLUM Ultra-fine Vertical Mill

Capacity: 0.2-45 t/h

Especially in the field of ultrafine grinding and processing of white non-metallic minerals, it has excellent performance and can provide high-quality fillers and additives for papermaking, coatings, plastics, rubber, PVC, ink and other industries.

1. Lining Plate

• On-sale

• After-sale

CE, ISO9001

factory sell directly

30 years experience, professional

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CPT,DDU,Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T,L/C,Western Union

Description of CLUM Ultra-fine Vertical Mill

CLUM ultra-fine vertical mill is a new type of milling equipment that includes grinding, grading, conveying, secondary powder selection, and finished product packaging. It is a large-capacity ultra-fine grinding and separation equipment developed by us, based on our 20 years of research and operation experience in the grinding industry. It is suitable for the production of fillers and coating calcium carbonate in large paper mills and the processing of other large-volume ultra-fine powders.

Max feeding size: 30mm

Processing ability: 0.2-45 t/h

Fineness of finished product: 325-3000 meshes

Application of CLUM Ultra-Fine Vertical Mill:

CLUM ultra-fine vertical mills are widely used in chemical, metallurgy, non-metallic mining and other industries, suitable for huge capacity producing, widely used in grinding non-flammable and non-explosive materials under 7(the Moh's hardness), such as quartz, feldspar, mica, calcite, talc, apatite, gypsum, fluorite, limestone, dolomite, granite, fly ash etc.

Main Features of CLUM Ultra-fine Vertical mill:

• Good quality of finished products: Fineness of finished products can be adjusted flexibly. Primary powder production can reach D97=10μm-20μm while the next powder separation attains D97=4-5μm easily. Finished products have advantages of high content of fine powder, high whiteness and more compact granularity

• The finished product has low power consumption, High grinding efficiency

• Advanced control system, saving labor force

• Use special wearable alloy materials, long service life of mill

• High production capacity

• No clang and slight vibration when the mill is working, fully sealed and environmentally friendly

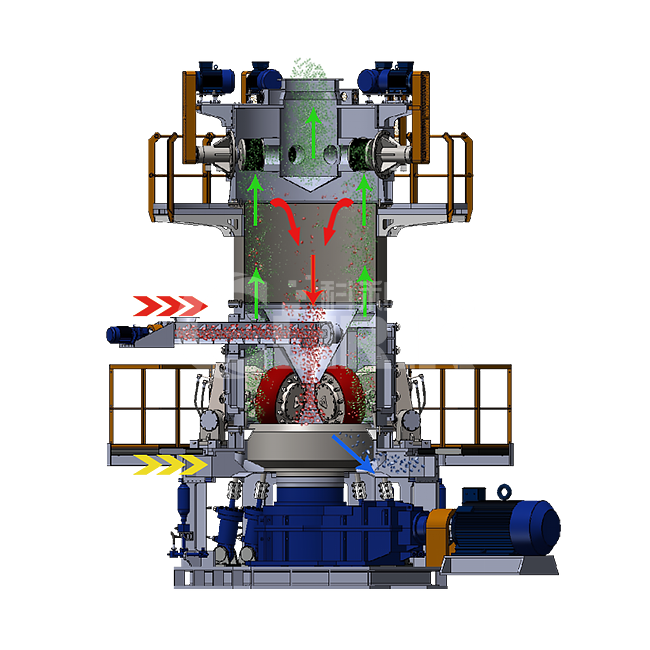

The Working Principle of CLUM Ultra-Fine Vertical Mill:

The motor of the main machine drives the milling disc to rotate through the reducer. At the same time, the airflow generated by the high-pressure fan enters the main machine from the air inlet. The material is fed into the main machine of the vertical mill through the feeding screw and falls into the center of the milling disc. Under the action of centrifugal force, the material is scattered from the center of the milling disc to the surroundings.

When passing through the roller table area on the grinding disc, the large pieces of materials are directly crushed under the pressure of the grinding rollers, and the small particles of materials are pressed and then subjected to inter-particle grinding to further pulverize until they become powder.

The powdered material continues to move to the edge of the grinding disc until it is taken away by the strong airflow from the air inlet. When the material in the airflow passes through the upper separator, under the action of the centrifugal force generated by the high-speed rotating impeller, the coarse particles fall back into the grinding disc After grinding, the qualified powder passes through the powder selection system with the airflow and is collected by the dust collector, which is the finished product.

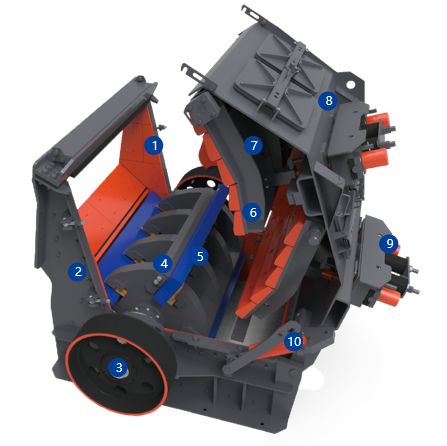

Structure and Composition of CLUM Ultra-fine Vertical Mill:

2. Lower Frame

3. Shaft Pulley

4. Rotor

5. Blow Bar

6. Impact Plate

7. Impact Rack

8. Upper Frame

9. Hydraulic Adjustment Device

10. Hydraulic Jacking Device

Parameter of CLUM Ultra-fine Vertical Mill:

Main configuration and production

Model

Item

CLUM1425

CLUM1632

CLUM1736

Working Diameters(mm)

1400

1600

1700

Number of rollers(pieces)

3

3

3

Number of classifier(pieces)

5

7

7

Power of classifier(Kw)

5X15

7X15

7X(15~18.5)

Main unit power (Kw)

250

315

355

Blower power(Kw)

200

250

315

Feed size (mm)

<10mm

<10mm

<10mm

Moisture of feeding material

<3%

<3%

<3%

Less than 2μm=34%

output(t/h)

11-14

13-17

15-19

Less than 2μm=46%

output(t/h)

7-8

9-10

11-12

Less than 2μm=60%

output(t/h)

3-4

/

/

Material: based on calcite

Particle size distribution: measured by micro laser diffraction particle size analyzer in British Malvern3000 instruments

Customer Case of CLUM Ultra-fine Vertical Mill:

Our Workshop of CLUM Ultra-fine Vertical Mill:

Our Service:

• Pre-sale

Free to help customers in equipment selection and scheme design

You are always welcomed to visit Clirik! Visit our prototype and showroom.

Strictly implement quality standards, and guarantee the quality of products shipped

Strictly implement the standard process of preparation and delivery, timely and accurate stock preparation, and rapid delivery

Overseas professional installation team provides technical guidance for equipment installation and commissioning

Train the start-up process, teardown method, common problems and maintenance service.

Professional after-sales service team, 24 hours response to customer needs

FAQ:

1. What is the production process of CLUM ultra-fine vertical mill?

A. Crushing system: raw material silo→feeder→jaw crusher→belt conveyor→de-ironing separator→hammer crusher→elevator→dust

collector→surge bin.

B. Grinding system: quantitative belt scale→elevator→spiral conveyor→de-ironing separator→ultrafine vertical mill→pulse dust

collector→fan→air door.

C. Conveying system: elevator or pneumatic conveyor.

D. Auxiliary system: agent adding system, compressed air system, water cooling system.

2. why should you buy from us?

3. what payment methods can we accept?

Company strength

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a pioneer enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

So far, we have established a whole production chain, the products covermicro powder grinding mill, high pressure grinding mill, European version coarsegrinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on. They are widely used in the industry of mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering and so on. Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, and America, etc.

We still insist on the communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always is in the domestic front. Based on the principle of constant innovation and quality guarantee, customer foremost, we are able to provide our customers not only the highest quality products at the most favorable price but also the most reasonable solution, such as the selection of the equipment,optimized process configuration and a full range of technical support, therefore we always follow your steps, pursue your value and achieve your benefit.