Sillimanite is a natural magnesium-containing mineral whose main component is magnesium oxide (MgO) and its chemical formula is MgO·SiO2·H2O. Sunstone has the following properties:

Appearance: Usually white, light gray or light green, with glass luster.

Hardness: Mohs hardness is 3.5-4, which has a certain hardness.

Density: The density is 2.8-3.1 g/cm³ and has a certain weight.

Chemical properties: Weakly alkaline, soluble in acid.

Thermal stability: It has good thermal stability and can remain stable at high temperatures.

Slimestone is an important mineral resource with wide application value. Silite can be crushed and ground to make refractory materials, building materials, chemical raw materials, ceramic raw materials, etc.

Sunline stone is mainly used in the following aspects:

Refractory materials: Silaite has good refractory properties and can be used to make refractory bricks, refractory crucibles and other refractory materials.

Building materials: Silica stone can be used to make artificial stone, wall tiles, floor tiles and other building materials.

Chemical raw materials: Silamenite can be used to make chemical raw materials such as magnesium salts and magnesium alloys.

Ceramic raw materials: Silite can be used to make ceramic glazes, ceramic bodies and other ceramic raw materials.

The crushing and grinding of evening stone

Sunstone can be broken and ground into powder. The crushing and grinding process of silicate stone is as follows:

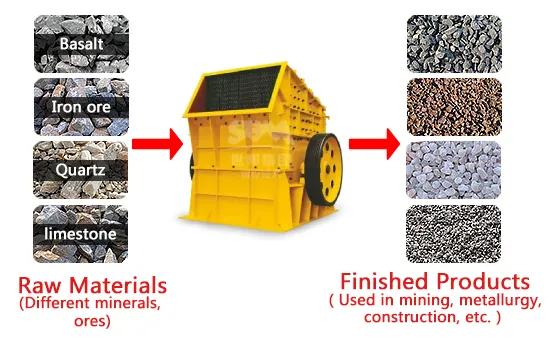

Crushing: Crushing sylphite ore into fine materials of a certain particle size. Commonly used crushing equipment includes jaw crusher, impact crusher, cone crusher, etc.

Grinding: Grind the crushed silaline fines into the required fineness. Commonly used grinding equipment include ball mills, Raymond mills, ultra-fine grinding mills, etc.

Grading: The ground silica powder is graded according to particle size to meet the needs of different users. Commonly used classification equipment include vibrating screens, air classifiers, etc.

Packaging: Pack the graded silimanite powder for easy transportation and storage.

Commonly used equipment for crushing and grinding stone is as follows:

Jaw crusher: Jaw crusher is a commonly used crushing equipment, suitable for crushing various medium hard materials.

Impact Crusher: Impact crusher is an efficient and energy-saving crushing equipment, suitable for crushing various medium hard materials.

Cone Crusher: Cone Crusher is a crushing equipment suitable for crushing hard materials.

Ball mill: Ball mill is a commonly used grinding equipment, suitable for grinding various medium hard materials.

Raymond mill: Raymond mill is an efficient and energy-saving grinding equipment, suitable for grinding various non-flammable and explosive materials.

Ultra-fine grinding mill: Ultra-fine grinding mill is a kind of equipment suitable for grinding ultra-fine powder.

When crushing powdered sulfur stone, you should pay attention to the following matters:

Crushing: Appropriate crushing equipment should be selected according to the hardness and particle size requirements of the silicate.

Grinding: Appropriate grinding equipment should be selected according to the hardness and fineness requirements of silamen.

Grading: Appropriate grading equipment should be selected according to the purpose of the silaline stone.

Packaging: Appropriate packaging materials should be selected according to the use of silamen.